Recovery, rebuilding,

re-tooling

Help us revive and inspire american manufacturing

Our small manufacturing shop needs tooling, power, and most importantly, your help.

Its no secret that many small manufacturers like ours closed in the pandemic years, or are just hanging on in today’s turbulent economy. To keep our doors open and to continue to serve the Jeep and local communities, we took on a lot of debt, and are struggling to keep up on high interest payments, while we continue to invest in our fellow countrymen and women by building our parts with the highest quality domestic materials.

Ive held off on accepting donations for our benefit for some time, but recently, several followers of our social media pages asked if we had a place where they could assist, and looking at the growing stack of bills, now seems like a good time.

All funds raised will go first to a power conversion setup for our “new” equipment, and then to help with outstanding debts built up over the last few years. Once we are back on solid ground, we can then hire on part or full time help, and offer good paying local manufacturing jobs. I promise that any funds will be used in the spirit of the donation, and am grateful for your empathy and time. See below for a list of how we are using funds, and a running total.

- Bryan, Founder, Azzy’s Design Works and TeamADW

(donation levels set by the site, we are thankful for anything you can spare)

Reach out to us for any of your badging, laser cutting,

custom packaging, or other small manufacturing needs here.

Transparency

As we utilise funds, it is important to be open about the uses.

This section we will keep updated with purchases and gifted items that are being used for our this project. We understand that the US dollar does not go as far as it once did, and are making the best efforts to spend wisely. Any funds not covered by donations are sourced from personal savings or credit cards.

Total graciously donated (as of 5/28): $507

Estimated total spent : $2,760

Purchased :

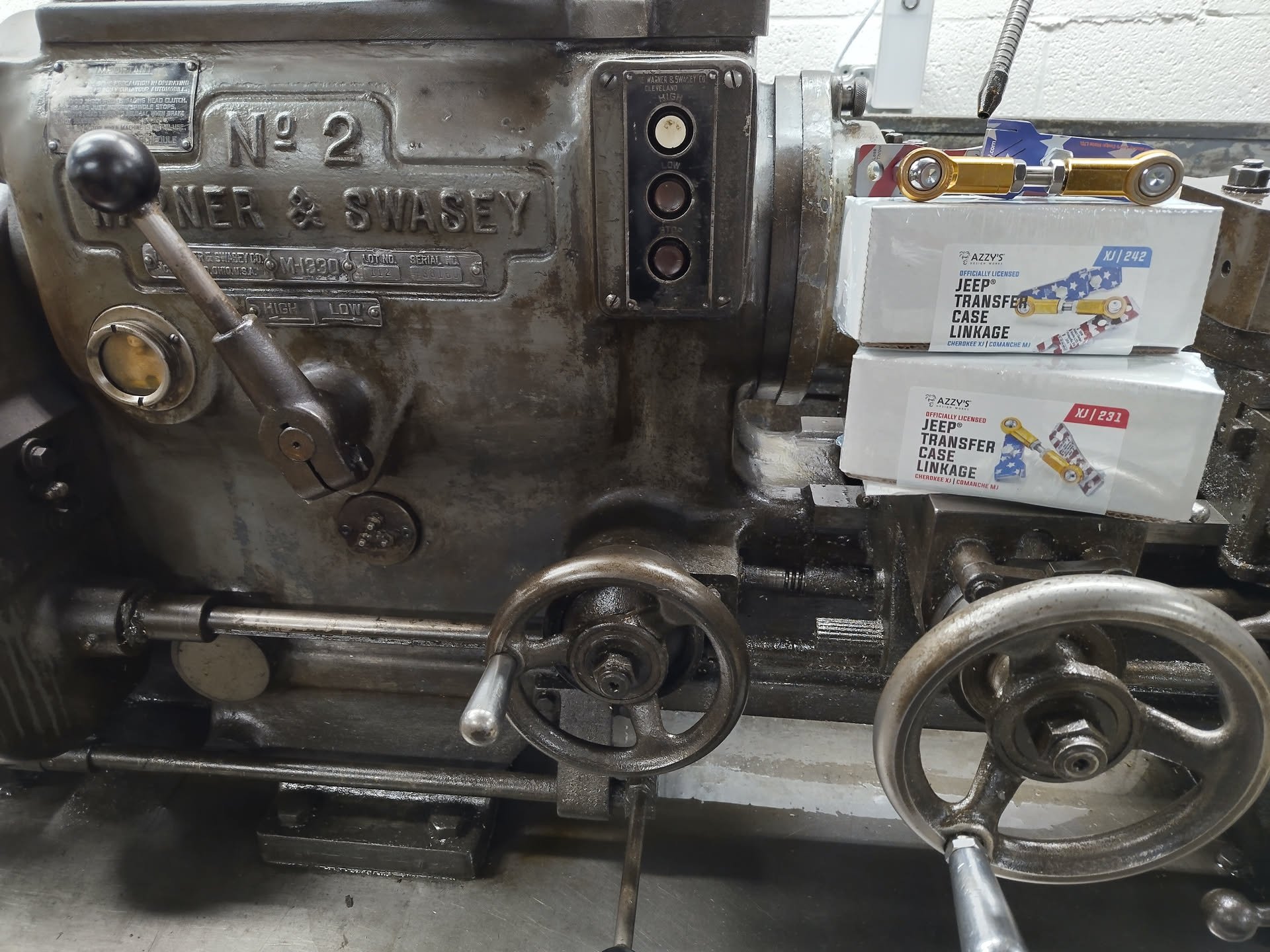

W&S No. 2 Turret Lathe and original tooling

Atlas Co. No1 Shaper

Warner & Swazey “Turret Lathe Service Manual” reproduction from Ozark Tools

Turret Lathe Operators Manual by Warner & Swazey Co, pub. 1940

North American Power Converters Model 310-B Rotary Phase Converter from Electric Motor Supply in Finleyville PA

38 feet of 10/4 SOOJ cable + misc electrical supplies

Sunbelt 12K trailer rental

Gifted :

Antique American sensitive spirit level - Tim S.

Various electrical small tools, boxes, supplies - Al S.

Specialty equipment moving skates and jacks supplied on loan - Gabe C.

Time and professional assistance - Andrew R., Keith B., Paul B., “Doc” N.

Why give?

-

✽

TeamADW has been serving the Jeep community with American made gauges and other parts since 2012, always insisting on domestically produced supplies and materials.

-

✽

We recently aquired a 1940’s turret lathe in order to make linkage turnbuckles and other parts that are too expensive to order in bulk. The machine requires a hefty and expensive specialty power converter in order to run it here in our shop, as well as the wiring and boxes.

-

✽

Help us launch our machinery how to videos, to help educate younger makers on the tools that built our country and still work to build awesome new parts today. Help us share manufacturing knowledge, and inspire a new generation of American made goods!

-

✽

Team ADW at its peak had 3 full time employees and a part time assistant, with plans to bring on another full time assembly tech and part time video editor. We currently run on 1 full time person and occasional part time help when funding allows.

-

✽

Help us bring the following ideas and prototypes into custom products: XJ door pockets; custom pool ball shift knobs; a shift ball adapter for your AW4; Tacoma gauge face kits; Gen2-3 Cherokee XJ badges… and more!

-

✽

In order to comply with Pennsylvania state demands during 2020 for keeping our doors open, we took on a sizable SBA loan in order to afford air handling equipment. Unlike many loans from this time, these are not excusable, and your help will catch us up.

Make a donation.

Any funds raised will go first to a power conversion setup for our “new” equipment, and then to help with outstanding debts built up over the last few years. Once we are back on solid ground, we can then hire on part or full time help, and offer good paying local manufacturing jobs. I promise that any funds will be used in the spirit of the donation, and am grateful for your empathy and time.

When I am able to, I will pay this forward in our community.

- Bryan, Founder, Azzy’s Design Works and TeamADW

(donation levels set by the site, we are thankful for anything you can spare)

With a little Help from our friends…

We were able to re-launch our once biggest product, the Jeep Cherokee Transfer Case Linkage. Here’s a clip of some of that production that was made possible by our donors:

Running right hand threads on our W&S no. 2 Turret Lathe, from 304 stainless rod.

FAQs

-

Yes, Ive been making custom Jeep accessories since 2012, doing this as a side gig, while working as a signage designer and technology director for a local company.

The last few years, especially 2022-2023 have hit us with high costs, and during that time, we had huge growth in overseas copies, with little or no help from national platforms or our own federal representation. Because of that, we’ve only been able to scratch together a few pre-orders here and there to make batches of parts. -

Over the last 2 years we have cancelled expensive and underperforming services, found alternatives to subscription software, changed suppliers where necessary. We’ve cut back on social media ad spending where it doesn’t reach people. We’re working on new products, and updating old ones, and juggling supply orders according to sales to not take on new credit card debt.

We are working with several clubs to provide them with badges, and have a big backlog of products that need finished prototypes, and all of the work that comes with online selling.

We’ve tapped into family and friends as much as possible, who have been graciously stopping over to help with assembly and shipping. -

The machine above is a Warner & Swazey Number 2, a six speed geared turret lathe. These machines are the predecessor to CNC setups, and allow for the making of small parts in a quick and consistent manner. Our was sold to us by the shop that used to make our center rods, along with the tooling we need to make them again.

The power? These machines require 3 phase alternating current (the electricity in most homes is single phase) to power the huge 5 horsepower motor and feed system. While this is available in industrial settings the cost for install and use is staggering, and over the top for our needs. That’s where a Rotary Power Converter comes in, which uses a special motor configuration to create the other phases of electricity the equipment needs to run. As an extra bonus, we can use that same circuit to run our other 1940’s lathe, a South Bend 10” machine.

A rotary converter large enough to start the machines is at least $1700, and we also need 4 conductor shielded wire, as well as a junction / breaker for that circuit. And to pay an electrician to make sure we won’t start any fires! -

Back in 2015, I had the chance to participate in a new makerspace idea, called Techshop. For a monthly membership, you got access to a huge varied workshop, could reserve tools and equipment, and as part of being certified to work on any machine, you had to take a basic safety and operation class.

Many of these classes we took just to learn a new skill or get inspiration for projects we were stuck on. I learned a ton about lasers, how to run a CNC router, vacuum former, 3d printers, and more. Techshop sadly closed its doors in 2019, but I have lots of similar tools in the ADW shop, and people ask about them all the time. So my plan is to create short description videos, dos and don’ts videos, and project idea videos for the equipment we have here, including the 2 lathes.

Not fighting finances so often will give me the time and peace of mind needed to continue developing these ideas.